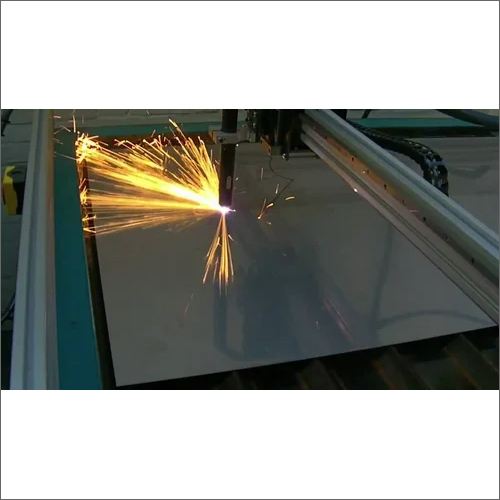

Industrial Laser Cutting Services

Product Details:

Industrial Laser Cutting Services Price And Quantity

- 250 Kilograms

Product Description

We are actively engaged in offering our clients Industrial Laser Cutting Services. These services use a Laser beam to vaporize, melt, or otherwise gradually remove material. Industrial Laser Cutting Services are carried out by experts of industry using advance cutting techniques. Moreover, these services are available at reasonable rates to the clients.

Laser Cutting Services

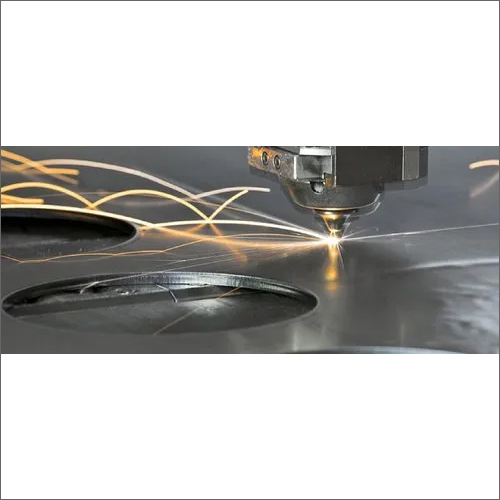

Laser cutting services refer to the process of using a high-powered laser beam to cut precise and intricate designs into various materials. It is a popular method for cutting and shaping materials across different industries, including manufacturing, engineering, automotive, aerospace, and even in hobbyist and artisan applications. During laser cutting, a focused laser beam is directed onto the material, which heats and melts or vaporizes it, creating a clean and accurate cut. The laser beam is controlled by computer numerical control (CNC) technology, ensuring precise and repeatable cuts with minimal material wastage. The CNC system follows a digital design file or pattern, guiding The laser to cut along the specified path. Laser cutting services offer numerous advantages over traditional cutting methods, such as:

Precision and Accuracy: Laser cutting provides high levels of precision, allowing for intricate and detailed cuts. It can achieve tight tolerances and produce clean edges, enabling the creation of complex and intricate designs.

Versatility: Laser cutting can work with a wide range of materials, including metals (such as steel, aluminum, and titanium), plastics, wood, acrylic, fabric, leather, and more. The process is adaptable to different thicknesses and can handle both thin and thick materials.

Speed and Efficiency: Laser cutting is a fast and efficient process, enabling quick turnaround times for projects. It eliminates the need for manual labor-intensive cutting methods and reduces production time.

Minimal Material Wastage: Laser cutting is a non-contact process, meaning there is no physical tool that directly touches the material. This reduces the risk of material damage and minimizes wastage, making it a cost-effective option. Complex Shapes and Intricate Designs: Laser cutting allows for the creation of intricate and complex shapes that may be challenging or impossible to achieve with other cutting methods. It offers design flexibility and opens up possibilities for innovative and customized products.

Laser cutting services are commonly used in various applications, including signage and lettering, architectural models, automotive parts, electronic components, jewelry making, prototyping, and industrial manufacturing. By utilizing laser cutting services, businesses and individuals can achieve precise, high-quality cuts that meet their specific requirements